Ready to Build TMT Bars

What is Primary Ready to Build Steel?

Why Choose “Primary Ready to Build TMT Bars”?

Zero Wastage: No overlapping, Perfect Shapes, overlapping increase the cost by increasing the extra 20% steel in the structure

Fast Construction: best buy ready to use steel and reduce the construction time and cost of the construction of your home or project

Perfect Bending: Get perfect angles on bends, bending shapes that are manually tough to shape, perfect angle and bends give more strength to the structure

Least Labour Requirement: Here less labor is required to handle the steel, cutting, bending and tying requires lots of requirement but by primary steel ready to build is a solution for less labor requirement

Highly Customized Designs: Primary Steel Ready to Build can provide you steel design requirements as per your project need. our highly skilled professionals analyzed your need and give you the best designs in a cost-effective way

Less Working Capital: By choosing Ready to Build solution working capital can be reduced by less inventory & labor management

Timely Delivery: Primary Steel provide timely delivery of your steel requirements so that you finish your project on time

Better Inventory Management: Primary Steel Ready to Build help you to manage your inventory by providing your steel requirement as per your project needs to Strengthen Brand Value By choosing Ready to Build solution you can finish your projects on time and completing the project on time always produce great value for business and creates or strengthen a brand value

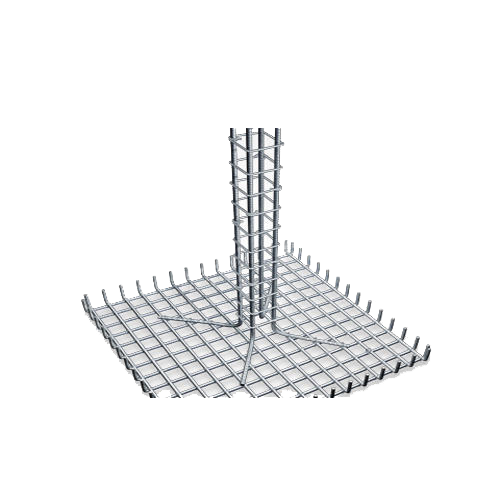

What is Primary Ready to Build Steel?

The process involves the cut & bend, couplers, and BBS development services which aim to offer the customized rebar shapes required at construction sites.

In the era of fast-growing infrastructure in India, there are several traditional processes still followed by contractors like preparing TMT bars according to the constructive shapes which required much-skilled labor and time.

Altogether it involved a lot of wastage, but a customer has to bear the overall cost.

To avoid hazardous steel modifications, we at Primary Steel introducing a simple way to solve a big problem in the construction industry.

We offering the ready to build steel at your doorstep in a convincing and affordable way.

Just ask your requirement, we deliver you the ready to build steel, which will definitely save a lot of bucks in terms of cost and time.

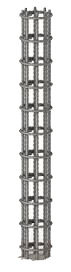

Cutting and Bending of Steel is one of the most important aspects of the construction industry.

This could be done manually on-site, which may result in large space of the storage of steel, inaccurate dimensions, and improperly bent bars.

On the contrary, you could give us the bending schedule, and receive Primary Readymade steel (Cut and bent) using superior automated machines with the perfect angles according to your bending and building schedule.

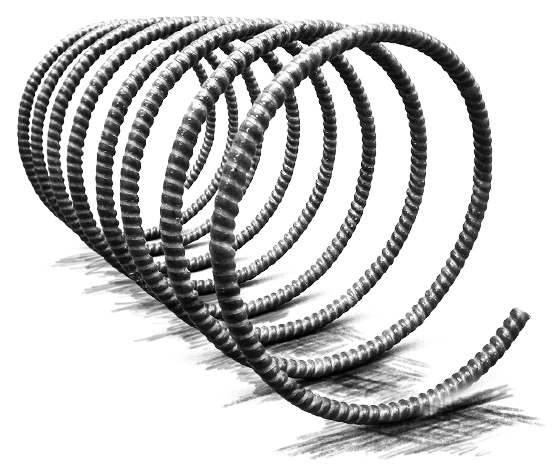

Stirrups (Cut & Bent)

The cut and curve structures required in development regularly utilize rebars of various shapes and sizes.

Regularly cutting and bowing of the rebars is done at the development site by the incompetent workers.

Since it is physically done by the workers, there are high odds of errors and wasteful aspects of the framework.

There are numerous different difficulties that are looked at by changed partners amid the development procedure that incorporates auspicious accessibility of material, talented work deficiencies, wastages, scrap transfer, and so forth.

Cut and curve benefit under Primary Steel Ready Build goes for giving altered states of rebars required at the development sites.

With Ready Build, the development organizations don’t have to stress over the accessibility of Stock Keeping Units required in the Cut and Bend structure.

The Ready Build Centers alter the lengths of the rebars and curve them at the required points as per the undertaking’s outline. It is equipped for making the normal shapes stirrups to complex helical shapes.

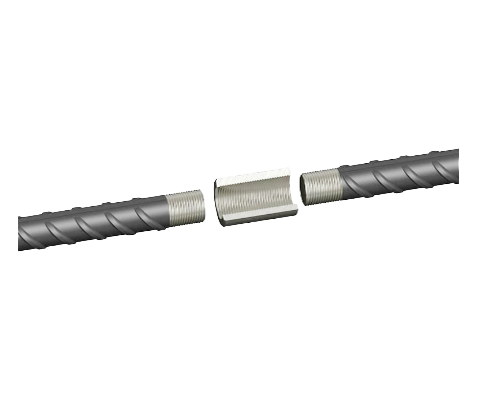

Couplers

What are couplers?

Couplers are basically utilized to bind the steel in a solid way which strengthens the bar joints, it’s a kind of hollow mechanical structure that is build to frame mechanical joints.

The utility of a coupler is to strengthen bar joints between two rebars, the current processing to joint the rebars called “lapping”.

Lapping is basically a process to bind the two bars with each other which require skilled manpower and adequate equipment and then coupled with wires to joint the bars.

The process is a little complicated, the skilled labor is required to finalize the process, the ordinary lapping process involves additional material like rebars, wires, and others whereas coupling through couplers is more convenient, affordable, and strong which leads to overall better and strong infrastructure.

Primary steel Ready Build’s Couplers comply standard industry norms to ensure the chemical configuration of all products matches their advanced specifications. We supply the best range of couplers according to requirements with the presence in all over India.

We at primary steel has a wide range of coupler available according to requirement, Our motto is to offer the great steel products all the time with innovative ideas we explore the best combinations of the Steel industry.